Services

State-of-the-Art CAD/CAM System

Tolland Machine uses Mastercam, (the industry leader in CAD/CAM) for both 2D and 3D CNC programming and tooling design. We can receive and support your digital datasets in all standard file formats, saving us time and you money. Our extensive experience with CAD/CAM allows us to set-up and program your jobs in hours instead of days, providing you with the flexibility you need for quick responses to critical requirements.

At Tolland Machine, we are committed to state-of-the-art technology to make sure our service remains the best in the business.

CNC Milling

Tolland Machine has six CNC Machining Centers, with 4th axis capabilities and pallet type machines for high production runs. With the support of our CAD/CAM system, we are able to program jobs off line as well as design tooling required while our machines are running production parts. This allows for maximum efficiency and minimizes set up cost giving us the ability to quote small quantity part runs competitively.

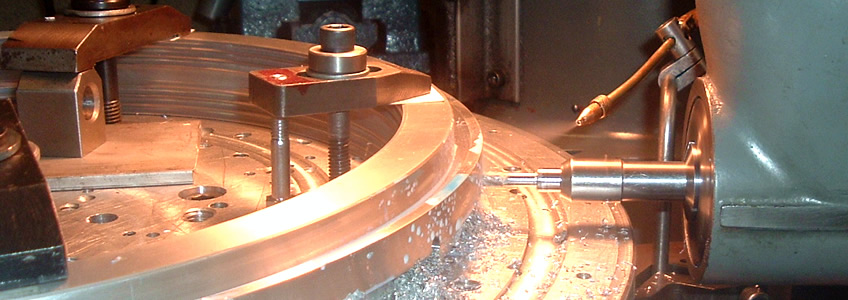

CNC Lathes

Tolland Machine has six CNC lathes, with bar feed capabilities, parts catchers and tail stocks for high production runs. With the support of our CAD/CAM system, we are able to program jobs off line as well as design tooling required while our machines are running production parts. This allows for maximum efficiency and minimizes set up cost, giving us the ability to quote small quantity part runs competitively.

Fabrication & Welding

Tolland Machine provides Mig & Tig welding, along with small parts fabrications, assemblies, small parts rolling and bending. We also provide laser and water jet cutting services.

Reverse Engineering

We offer reverse engineering services on customer supplied parts. Tolland Machine works with several of our customers to provide them with metallurgical, dimensional and mechanical information on their parts. We use the latest technology and supply a CAD model of parts and tooling fixtures for manufacturing of parts.